Popular Design for Automatic Screw Feeder - Food grade compact conveyor belt elevator feeder for auto packing system – Pack King

Popular Design for Automatic Screw Feeder - Food grade compact conveyor belt elevator feeder for auto packing system – Pack King Detail:

Product parameters

|

Hopper Capacity |

140L/ 150L |

|

Conveying Capacity |

3- 5M3/ H |

|

Power |

0.3KW |

|

Voltage |

AC220V |

|

Frequency |

50HZ/ 60HZ |

|

Weight |

105KG |

|

Machine Packed dimension |

1380mm (L) X370mm (W) X900mm (H) |

When the material passes through the sieve bar on the tank, the smaller material can fall through the gap of the sieve bar, without going through the next crushing process, which has the effect of screening. Used for temporary storage and transportation is dry, the free flow of food and non-food will mainly flow or no flow of temporary storage and feed powder or granular food bucket elevator or vibrating screen, apply to food, hardware, chemical and other industries, such as sugar, potato chips, soybean, biscuits, rice, grain, peanuts, a variety of materials such as feeding bucket elevator.

It uses electromagnet principle for power, the use of vibration will be transported to the bucket bucket bucket elevator, automatic operation. Its highly hygienic design and all-stainless steel construction ensure the machine is suitable for the most demanding applications, durable, easy to clean, and without backup, making it a good choice for the food industry.

Product features

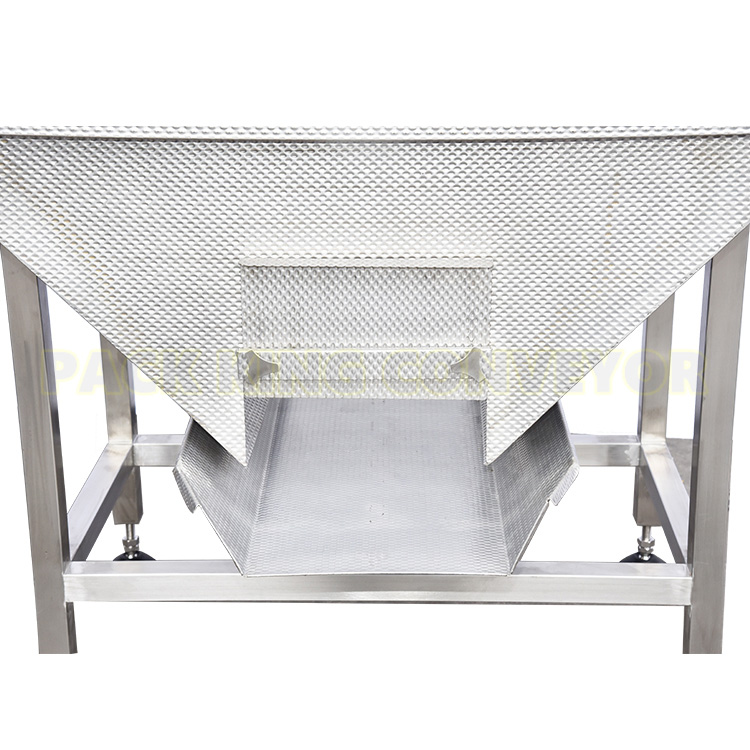

1. The bin is welded with 304 stainless steel material and can be disassembled.

2. The amplitude can be adjusted at any time to control the flow, convenient and stable.

3. Electromagnet type mechanical vibration, simple structure, convenient installation and maintenance.

4. Feeder (electromagnetic vibration feeder) vibration is stable and strong, so that the product transmission is uniform.

5. Reliable work and long life.

6. High quality and reliable work.

7. Light weight and small size.

8. Low noise, less power consumption, no impact material phenomenon, machine environmental protection.

9. Low maintenance and easy maintenance.

10. High efficiency and large feeding capacity.

11. Dust pollution can be prevented when enclosed structure fuselage is used.

12. Can be customized according to customer needs.

Product detail pictures:

Related Product Guide:

With a complete scientific quality management system, good quality and good faith, we win good reputation and occupied this field for Popular Design for Automatic Screw Feeder - Food grade compact conveyor belt elevator feeder for auto packing system – Pack King , The product will supply to all over the world, such as: Russia, Senegal, Iraq, In order to meet more market demands and long-term development, a 150, 000-square-meter new factory is under construction, which will be put into use in 2014. Then, we shall own a large capacity of producing. Of course, we will continue improving the service system to meet the requirements of customers, bringing health, happiness and beauty to everyone.

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!